High Temperature Removable Blankets and

Insulation for Engines & Generators

For Exhaust System Components: Mufflers & Silencers,

Turbo-Chargers, Flanges & Pipes

· Meets MIL-I-24222, USCG 164.009, ASTM E84 and UL 2200

Insulation for Engines & Generators

For Exhaust System Components: Mufflers & Silencers,

Turbo-Chargers, Flanges & Pipes

· Meets MIL-I-24222, USCG 164.009, ASTM E84 and UL 2200

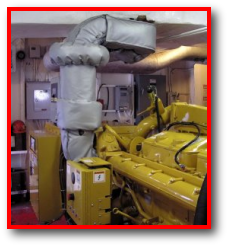

Custom fabricated removable insulation blanket systems for engine and generator exhaust components such as mufflers, turbo-chargers and pipe feature high temperature capability, reduction of thermal radiation and convection within the engine room and sound reduction. Used for marine powerplants & generators and stationary backup power systems for industrial, commercial and municipal installations.

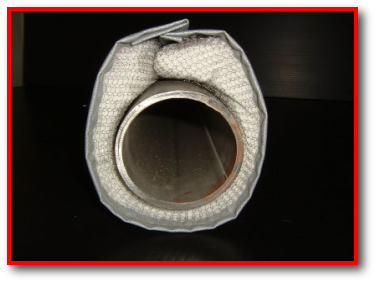

A thick needled fiberglass or silica insulation is mechanically supported by a stainless steel or inconel mesh and an outer fabric of either silicone rubber coated fiberglass, aluminized fiberglass or silica. Fiberglass is suitable for most non-turbocharged reciprocating engines. Silica may be required for turbo-charged engines and is required for gas turbine engine applications.

A thick needled fiberglass or silica insulation is mechanically supported by a stainless steel or inconel mesh and an outer fabric of either silicone rubber coated fiberglass, aluminized fiberglass or silica. Fiberglass is suitable for most non-turbocharged reciprocating engines. Silica may be required for turbo-charged engines and is required for gas turbine engine applications.

Needled Insulation between outer layer of silicone fabric and inner layer of stainless steel mesh

A

B

Stainless steel support mesh

C

Silicone Rubber Coated or Aluminized Fiberglass outer fabric layer

The insulation material used meets MIL-I-24244 for low corrosiveness and also meets US Coast Guard 164.009 for incombustible materials.

Removable blanket sections are assembled with either locking wire or spring clips with stainless hook fasteners or mushroom cap rivits mounted on the fabrics.

Industrial Generator Removable Exhaust Insulation Blankets & Covers

Marine Engine & Generator Exhaust System & Piping Covers

We maintain drawing sets for most major brands using standard configuration components. For models not on file all we need is a table of dimensions for the components you need covered, or a hand drawn sketch, or if available a CAD drawing or blueprint. A photo of the installation helps if available.

Fabrication time is typically 1 week to 2 weeks after receipt of your order.

Fabrication time is typically 1 week to 2 weeks after receipt of your order.

A

B

C

Extreme environments require extreme solutions... high temperature heat protection

firesleeve, tapes, fireblankets, fabrics, ropes & gaskets for industry, aerospace,

marine, and military use from the industry leader in thermal protection solutions.

> Protects hydraulic / pneumatic hoses & lines, cables & wiring

> Reduces failures, unscheduled outages, maintenance & energy costs

> Provides protection to personnel from hot process piping & equipment

firesleeve, tapes, fireblankets, fabrics, ropes & gaskets for industry, aerospace,

marine, and military use from the industry leader in thermal protection solutions.

> Protects hydraulic / pneumatic hoses & lines, cables & wiring

> Reduces failures, unscheduled outages, maintenance & energy costs

> Provides protection to personnel from hot process piping & equipment

To Order Call: 610-906-3549

Or Fax PO to: 610-679-8592

431 State Street Box 1491 Ogdensburg, NY 13669 USA

116 Albert St - Suite 300, Ottawa, ON K1P 5G3

Or Fax PO to: 610-679-8592

431 State Street Box 1491 Ogdensburg, NY 13669 USA

116 Albert St - Suite 300, Ottawa, ON K1P 5G3

07/25-117

Commercial customers may

fax a PO to 610-679-8592

fax a PO to 610-679-8592

Extreme Heat Protection

from A-B Thermal Technologies

500°F to 3000°F / 260°C to 1650°C

from A-B Thermal Technologies

500°F to 3000°F / 260°C to 1650°C

TM

We Accept Visa / Mastercard and PayPal

For a better user experience please use our new site: ABTHERMAL.COM

Removable Exhaust Blankets & Shields